Capabilities

We use the latest technology to deliver on time and on budget.

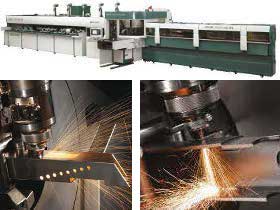

BLM Group LT8 Laser Tube Cutting Machine

Features of the LT8

- Integrates with 3D CAD / CAM Software

- Cuts Tube up to 8" x 8" x .500 Wall

- Reduces Design & Prototyping time

- Minimizes time to market

Watch VIDEO and see images of the various geometries this machine is capable of cutting.

CNC Ficep Saw with Drill

Features of the Drill & Saw Machine

- Integrates with 3D details using X-Steel, STRUCAD, DSTV, and AutoCAD software

- Beams up to 40'' x 362#

- Channels up to 40’’

- Tubes 16’’x 16’’

- Maximum hole 2’’

- Accuracy +/- 1/16'' over 40 feet

- Improves quality with part identification marks

CNC Ficep Thermal Coping Robot with Drill

Features of the Drill & Cope Machine

- Integrates with 3D details using X-Steel, STRUCAD, DSTV, and AutoCAD software

- Maximum Beam 42’’x 300’Tubes 19’’x19’’

- Plasma and Oxyfuel cutting

- Maximum hole drilling 2’’

- Accuracy +/- 1/16''over 40 feet

- Improves quality with part identification marks

CNC Ficep Plate Processing Machine

The plate-processing machine can process full sheets of plates and cut them into different shapes depending on specifications made. It has its own filtering system for plasma cutting.

Features of the Plate Processing Machine

- Integrates with 3D details, X-Steel, STRUCAD, DSTV, and AutoCAD software

- CNC controlled accuracy +/- 1.5 mm over 20 feet

- Max plate thickness 3’’

- Maximum plate size 60’’ x240’’

- Max drilled hole diameter 2’’

- Plasma and Oxyfuel cutting

- Improves quality with part identification marks

CNC HACO Hydraulic Guillotine Shear

Capacity of Shear 1/2’’ to 20'

Features of the Plate Shear Machine

- Material Handeling System can safely handle 1/2''x96''x 240'' sheets

- Minimum distortion from full capacity down to as light as 1/8" thickness without adjustment

Abrasive Blasting Facility

Before the fabricated material is painted it comes here; where it is prepped for painting.

Features of the Abrasive Blasting Facility

- Self contained and completely enclosed

- 20' W x 16' H x 50' L

- Abrasive reclaim floor collects the used abrasives

- Utilizes steel shot abrasive

- Dust collector keeps the environment clean and contaminant free

- Protects the environment by recycling blast abrasives

Paint Booth

Features of the Paint Booth

- 20' W x 16' H x 120' L

- Self contained and completely enclosed

- Meets all EPA requirements

- XtremeMix Proportioning System

- 100% solids pump

- Forced air curing and climate control up to 180 deg F

Benefits of the Abrasive Blasting & Paint Facility

- Economic

- Safe

- Environmentally Friendly

- Reliable

- Meet all EPA requirements